Timber material in ERP

Handling timber is in ERP is suprisingly hard in ERP. The thing it makes it difficult is that its handled both in Cubic Meters (M3), running meters and in PC’s.

Take a batch of timber with measurements (MM) 50x150x4500. Each piece of timber is about 0.03375 M3. ((50/1000)(1501000)/(4500/1000)) = 0.03375 M3.

Each batch of timber has different qualities – It has % of moist, FSC/PEFC quality marking, stress test and many more.

But the most important two are timber cross section and length.

Timber is usually sold in steps of 300mm length – 3000,3300,3700…6600 or even longer. Normally it stops at 6000 though.

So where to put these parameters and the length?

Lets put it to items.

If we put the length and parameters to item then we will quickly end up 100’s of thousands of items in ERP and it never stops because each time new quality parameter is introduced we need new item.

It will be a mess since selling wood is not so straight forward.

Customer might order 120 PC’s of 50x150x4500 = 4.05 M3 of wood from us but they are also willing to accept 50x150x4800 if we have that in stock, no problems.

If the length is in the item code then MRP will always trigger new purchase orders for each length and we need to swap the items on orders all the time.

Then there’s also purchase planning – we cannot say exactly what lengths we want to purchase from saw mill since wood is natural product and lengths depend what is available.

Instead we want to take together all our demand in cubic meters and say to the saw mill that we need 200 M3 of 50×150 raw material and we will accept lengts between 4000-6000.

Lets put cross section to items and length / parameters to lot (batch)

If we only leave cross section and maybe one or two quality parameter to item and put length and other quality parameters to batch we will get much more flex system.

Then we are able to create sales order for 50×150 for Quantity of 120 PC’s.

We still need some customization to say which lengths the customer wants. We can do that by customizing Business Central.

Here what we have done is created a way to choose length on the sales order which then triggers calculation that calculates the M3 of the order.

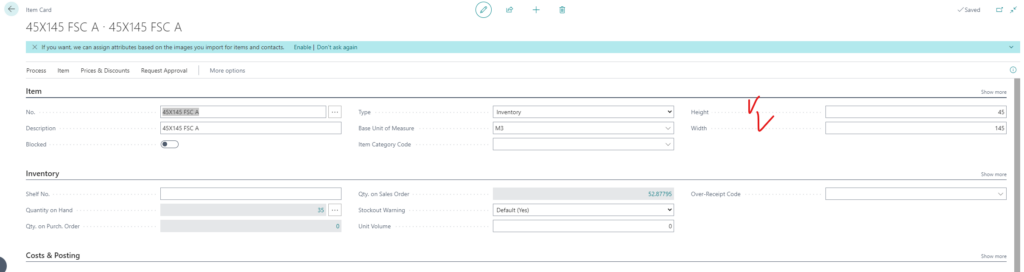

Item card is defined as following with width and length of the timber:

This will give us much flexibility since we will only have few number of item records.

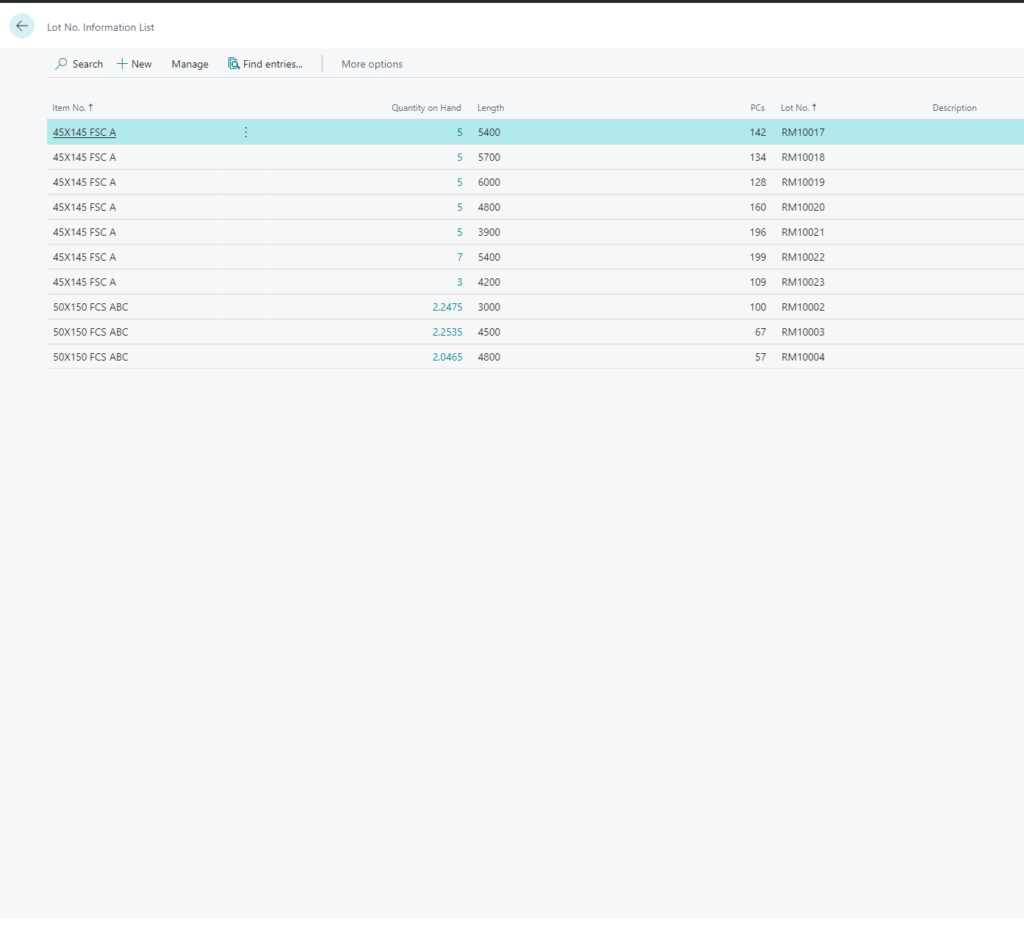

We can now select batches from inventory which we will ship with this sales order. We can combine different batches with different lenghts. We can take 30 pc’s of 50x150x4500 and take 90 pc’s of 50x150x4800 and customer will be happy.

From Lot No Information page we can see the M3 and PC’s of each individual lots:

Handling timber this way will give us much more flexibility